True Performance Manual Solar Shades

True Performance Manual Solar Shades ensure customer satisfaction with durable materials and a smooth roller clutch system. These cost-effective, energy-efficient shades from SWFcontract offer easy operation, effective daylight control, and stunning shade cloth. That’s true performance.

Commercial Window Treatments

True Performance Manual Solar Shades Details

Controls

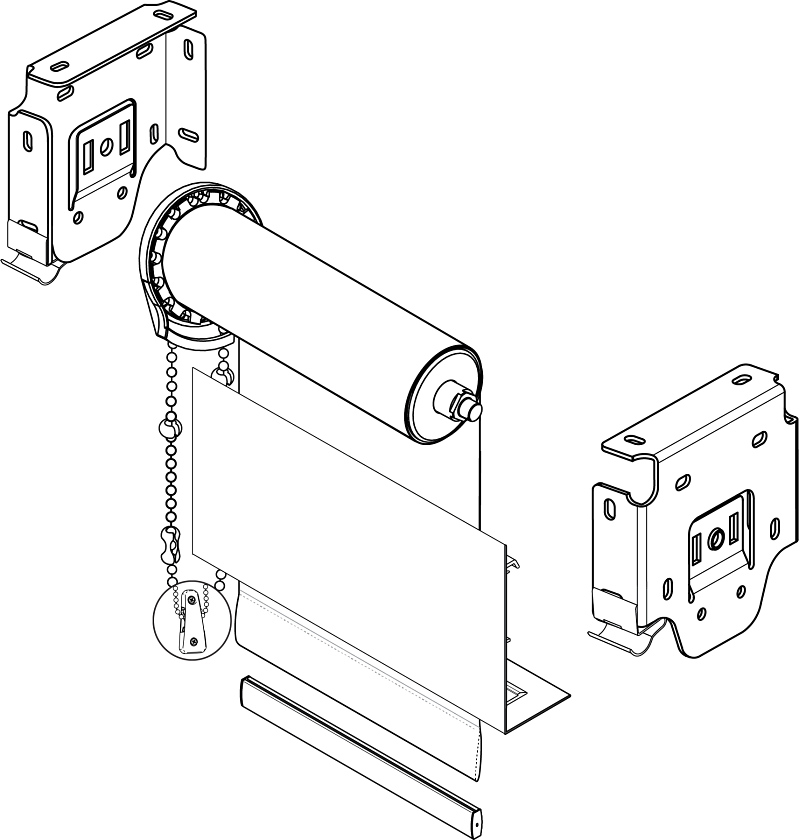

- The TruePerformance Clutch System consists of fiberglass-filled nylon for wear resistance, smooth operation, and corrosion resistance.

- The clutch uses a Velvetrol™ internal spring arrangement for a smooth pulling force that locks the shade in any position when operating the control loop.

- The clutch mechanism is inserted in the roller tube at manufacturing. The mechanism is bidirectional and does not require adjustment or lubrication.

- The control loop is a 10-pound stainless steel bead chain with bead stops attached to the chain to protect the shade from over-rotation.

- The idle end is constructed of high-strength, fiberglass-filled nylon with spring-loaded pin-end technology for wear resistance, smooth operation, and corrosion resistance.

- The lift assist system is a heavy-duty torsion spring located inside the roller tube. This mechanism reduces the pull force, allowing easy lifting of larger shades.

Fabrics

- Fabric options range from 100% opaque to 14% open.

- Shades with railroaded fabric may have heat-sealed seams.

- Heat-sealed fabric spline allows for easy shade band removal.

- Fully-enclosed heat-sealed hem pocket is standard.

- Solar and blackout shade fabric collections are antistatic, fade and stain resistant, and pass NFPA 701-1999 FR, and ASTM-G21 and G22.

- Solar and blackout fabrics feature options that are GREENGUARD Gold certified and FR rated NFPA 701.

- Fabric options also include ShadeDefense Antimicrobial Protection, our antibacterial and antifungal technology that meets ASTM G21 and ASTM E2180 test methods.

Options

- An optional 5″ pocket with lip provides ceiling tile support, or without lip provides a clean appearance in an exposed application

- 7-5/8″ pocket available for dual shades

- Closure plates

- Closure mounts with tile support and no tile support (lip)

- Side, sill, and center channels

- Dual and coupled shades

- External fabric-wrapped hem bar

- Plastic bead chain

Tubes

- Tube sizes include 1-1/2″, 2″, and 2-1/2″ diameters.

- Tubes are extruded aluminum engineered with a channel to accept fabric spline.

- Tube diameters and wall thickness provide optimal performance and minimal deflection. (Dimensions are determined by manufacturer based on fabric selection and shade size.)

- The TrueTrack Spline keeps fabric straight on tube, minimizing fabric tracking and creasing. Our unique co-extruded spline is heat-welded to the fabric, providing a secure attachment to the tube while allowing easy removal of the fabric band.

NOTE: The tube size is engineered based on the following: height of shade for length of fabric and thickness of fabric as it is spooled on the tube; deflection concerns based on the weight of the fabric; and common tube sizes across all shades to accommodate similar rollup speed, etc. Let the SWFcontract team help you with all the details.

Fascia

- 3″ and 4″ fascia front and back

- 7-5/8″ dual shade fascia

- Reverse roll fascia

Brackets

- Nonhanded brackets for easier mounting and superior performance.

- Color coordinated brackets blend seamlessly with fascia, unlike visible zinc-plated brackets.

- Shades are easy for installer to level, eliminating fabric tracking and reducing callbacks.

- Bracket covers are optional.

- Installation brackets are 16-gauge, corrosion-resistant, stamped steel, and can accommodate overhead, side, and face mounting.

- Brackets are powder-coated. Non-fascia brackets are available in white, vanilla, gray and black. Fascia brackets are available in white, gray, vanilla, bronze and black.

- Optional dual shade brackets hold two shades in one bracket assembly. Coupled shades are connected with a linked bracket mechanism.

Dimensions

| ALL FABRIC STYLES | WIDTH | HEIGHT |

| Minimum | 10-5/8″ | 6″ |

| Maximum | 192″ | 240″ |

Installation Considerations

| JAMB MOUNT | OVERHEAD MOUNT | |

| No Fascia | 3/4″ | 4-1/8″ |

| 3″ fascia | 3/4″ | 2-3/4″ |

| 4″ Fascia | 1-3/8″ | 3-3/4″ |

Installation & Operation

Download Installation Guide

Download LWRoller Fascia Installation Guide

Download Measuring Custom Chain length Instructions

Download LWRoller Cordless SmartPull Lift Outside Mount Installation Guide

Download LWRoller Fascia Skyline Bracket With Fascia Installation Guide

Download Roller Blackout Channels Installation

Download Angle Coupled Measuring And Installation

Download LWRoller Cordless SmartPull Lift Inside Ceiling Mount Installation Guide

Data & Specification Sheets

Download CSI Specification

Download Pocket Data Sheet

Download Manual Shade Clutches Data Sheet

Download TP SL20 Data Sheet

Download Fascia Data Sheet

Download No Fascia Bracket Data Sheet

Download TP SL15 Data Sheet

Download TP SL30 Data Sheet

Download Dual Manual Brackets Data Sheet

Download Chain Diverter Data Sheet

Download TP Dual Fascia Data Sheet

Download TP Dual Data Sheet

Download TP SL15 Fascia Data Sheet

Download Angle Coupled Fascia Bracket Data Sheet

Download Manual Fascia Data Sheet

Download Fascia Brackets Data Sheet

Download Closure Plates Data Sheet

Download Manual TP SL20 Blackout Data Sheet

Download Coupled Intermediate Bracket Data Sheet

Download Manual TP Coupled Blackout Data Sheet

Download Manual TP SL30 Fascia Data Sheet

Download Chain Tensioner Data Sheet

Download Blackout Channel Data Sheet

Download Manual TP SL20 Fascia Data Sheet

Download Manual TP SL20 Blackout Back Fascia Data Sheet

Download Manual TP Coupled Fascia Data Sheet

Download Manual TP Coupled Data Sheet

Download Side Sill Channel Data Sheet

Download Manual TP Coupled Data Sheet

Download Angle Coupled No Fascia Bracket Data Sheet

Download Manual TP Dual Blackout Data Sheet

Drawings

Download Manual Section SL10 Reg Roll With 3″ Fascia Wall Mount OWF Drawing

Download Manual Section SL15 Pocket With Tile Support And-2″ Closure OWF Drawing